Test Method

For Petroleum Products, cloud point and pour point of a petroleum product is an index of the lowest temperature of its utility for certain applications. The specimen is cooled at a specified rate and examined periodically. The highest temperature at which a cloud is first observed at the bottom of the test jar is recorded as the cloud point. The lowest temperature at which movement of the specimen is observed is recorded as the pour point. Automatic Cloud Point and Pour Point Analyzer with Integrated Panel PC.

- Cloud Point Analyzer conforms to ASTM D2500, D5771, D5772, D5773 and related test methods

- Pour Point Analyzer conforms to ASTM D97, D5853, D5950 and related test methods

- Stand alone system with Integrated Touch Screen Panel PC

- Direct Cooling system eliminates the need for solvent cooling baths

- One-stage cooling system provides temperatures as low as -40?C and a two-stage cooling system down to -80?C

- Cloud Point measured by light pulsed emission on I.R spectrum through a coaxial fibre optic

- Pour Point measured by two PT100 detection probes placed on the surface of the product and a mechanical moving arm bringing the test jar to a horizontal position

Cloud Point Detection

The cloud point detection system provides automated sample testing with the accuracy and repeatability in accordance with ASTM D2500, D5771, D5772, D5773 and related international test methods. The sophisticated dynamic measuring system emits a light pulse every 1?C from a coaxial fibre optic cable positioned above the test sample. The light pulse is then reflected off the silver bottom test jar to an optical sensor. The advanced software package analyses the response of the light pulse. The initial appearance of crystallization is monitored by light scattering, signifying the cloud point of the sample. All clear and transparent oils are readily measured by the detection system, regardless of sample colour.

Pour Point Detection

The pour point detection system provides automated sample testing with the accuracy and repeatability in accordance with ASTM D97, D5853, D5950 and related international test methods. The automated operation involves removing the sample from the cooling jacket at 3?C intervals and tilting it to a 90? angle as prescribed by the test method until no flow is observed. Contact of the cold sample with the two PT100 detection probes positioned just above the surface liquid level when the test jar is tilted identifies sample flow. The test jar is automatically returned to the cooling jacket and sampled again until no flow is detected for 5 seconds. The pour point result is then reported at 3?C higher than the temperature at which the sample ceased to flow in accordance with the test method.

Integrated Panel PC and Software Package

The Automated Cloud and Pour Point Analysers are complete standalone systems featuring an integrated panel PC with an advanced software package. The 6.4" TFT/LCD touch screen display has a resolution of 640x480 with a 262K colour scheme. All analytical parameters are graphed and displayed in real time as well as recorded in Microsoft Excel compatible file format. The software monitors the operation and performance of all the analyser components for proper data measurement, including the solenoid valves, cooling system, pressure sensors, and the Platinum resistance PT100 Class A temperature probe.

Cooling System

For various user applications, the automated cloud and pour point systems are available with either one-stage cooling for temperatures as low as -40?C or two-stage cooling for temperatures as low as -80?C. The direct cooling system features integrated gas CFC free motors compressors thus eliminating the need for a solvent cooling bath. The direct system is capable of rapid cooling, approaching -80?C bath temperatures in approximately 15 minutes, and utilizes less electricity than standard cooling systems. The rapid cooling feature combined with a consistent cooling profile system provides repeatable results with high test reproducibility. Multiple Configuration System-These automated sample cooling and physical property measurement systems can be configured with one, two, three, four and six test positions with one of five possible analytical heads at each position: cloud point, pour point, cloud & pour point, cold filter plugging point and freezing point. Standard and customized multiple configuration systems are readily available.

Specifications

- Conforms to the specifications of : KLA-1-TS: ASTM D2500, D5771, D5772, D5773; DIN 51597; IP 219, IP 444, IP 445, IP 446; ISO 3015 KLA-2-TS: ASTM D97, D5853, D5950; IP 15, IP441; ISO 3016 KLA-3-TS: ASTM D97, D2500, D5771, D5772, D5773, D5853, D5950; DIN 51597; IP 15, IP 219, IP441, IP 444, IP 445, IP 446; ISO 3015, ISO 3016

- Temperature Range: +80?C to -80?C (+176?F to -176?F)

- Resolution: 0.06?C

- Accuracy: ?0.1?C

- Repeatability / Reproducibility: as per standard test methods or better

- Data Storage: less than 60,000 analyses

- Electrical Requirement : 115V ? 15% / 60Hz ; 220V ? 15% / 50 to 60Hz

Dimensions

- WxDxH,in.(cm) : 26 x 23-3/4 x 31-1/2 (66x60x80)

- Net Weight : 176.5 lbs (80kg)

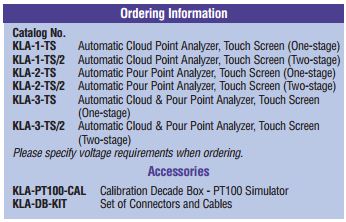

Request Quote