Test Method

For flash point determination of biodiesel, distillate fuels, new lubricating oils, residual fuel oils, cutback residua, used lubricating oils, mixtures of petroleum liquids with solids, petroleum liquids that tend to form a surface film during testing.

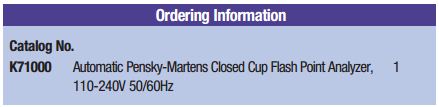

Automated Pensky-Martens Flash Point Analyzer

- Conforms to ASTM D93 and related specifications

- Flash Point Detection by Thermocouple and Ionization Ring

- Electric or Gas ignition: Software selectable, User Friendly Manual Switching

- Flash Point operation range between Ambient and 405°C

- Integrated Dual Fan System directly cools test cup and surrounding environment

- 8.4" LCD Touch Screen Interface makes for easy viewing and navigation

- Automatic Barometric Pressure Correction

- Fire Suppression System floods instrument with inert gas in the event of a fire

The Automated Pensky-Martens Flash Point Analyzer represents a perfect union of next-generation technology with traditional robust quality. The system software runs on an integrated processor PC running the latest Windows operating system. The 8.4" touch screen interface fully displays all operator parameters and results on a single screen. A three (3) position mechanical lift system for the cover and motor assembly is fully automated and software selectable: Open - Clean - Test for one touch positioning of the test cup. Comes standard with two flash detector systems including a thermocouple and ionization ring detection. Over 65,000 results of data can be stored on the local hard drive. Integrated Dual Fan System directly cools the test cup and the environment around test cup. Unlimited number of user programs including a quick test that safely tests from ambient, puts the flash point result into the EFP of the official run, and prompts user to refresh the sample, virtually assuring no fires ever occur. In addition, the instrument comes standard with an inert gas fire suppression system.

Specifications

- Conforms to the specifications of: ASTM D93 Procedure A, B and C; IP 34; ISO 2719; DIN EN 22719; JIS K2265; NF M 07-019

- Detection System: Thermocouple and Ionization Ring

- Temperature Range: Ambient - 405?C

- Heating Rate: In accordance to ASTM D93 procedure A, B and C

- Stirring Rate: 0 to 300 ? 5 RPM

- Cycle Time :5 minutes as per rapid fan cooling system

- Ignition Test Frequency: User selectable on per method basis

- Cooling: Integrated Dual Fan System: First (1) directly to cup, Second (2) to cool environment around test cup Barometric Pressure: Automatic Barometric Pressure Flash Temperature Correction

- Maximum Pressure for Ignition Gas: 1 psi, 40mBar/hPa, 16 in H2O

- Methods & Data Storage: Limited only by PC hard disk drive space

- Communication: - LIMS Connectivity via Ethernet and RS 232 ports , - Two (2) USB ports (1 - Frontm 2 - Back)

- Security: Three (3) level password protection

- Safety: Fire prevention, detection, and suppression systems standard

- Electrical Requirements: 110-240V 50/60Hz

- Temperature Calibration: Three Types come standard:

- 2 Point Sample Temperature (Standard)

- Multipoint (>2) Temperature Calibration (Available as Option)

- CRM Calibration - Built-In Software function to automatically correct as per CRM tested

Dimensions

- wxdxh,in.(cm) : 10 7/8 x 17.5 x 26 (27.63x44.45x66.04)

- Net Weight: 60 lbs (27.22kg)

Request Quote