Test Method

Tests the corrosiveness of LPG to copper by immersion of a polished test strip in the sample inside a test cylinder at elevated temperature. After one hour the test strip is removed and compared against the ASTM Copper Strip Corrosion Standards.

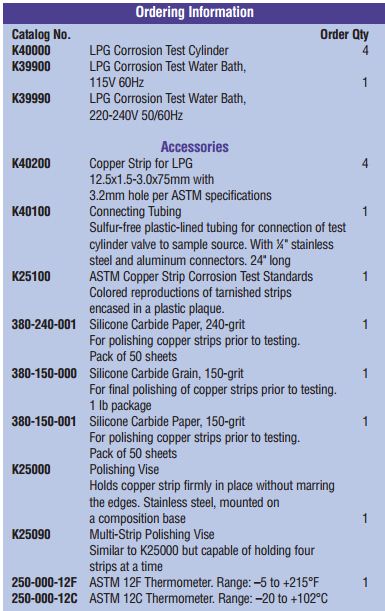

LPG Copper Strip Corrosion Test Apparatus

- Conforms to ASTM D1838 and related specifications

- Four-sample testing capability

Consists of LPG Corrosion Test Cylinders, Water Bath, Copper Strips, Polishing Materials and the ASTM Copper Strip Corrosion Test Standards.

LPG Copper Strip Corrosion Test Apparatus

Evaporates aircraft turbine fuel and motor and aviation gasoline samples under controlled conditions in accordance with ASTM specifications. Consists of a high temperature evaporation bath with 100mL test beakers and, for aircraft turbine fuels, a steam generator and steam superheater.

Evaporation Baths

- Conforming to ASTM D381 and related specifications

- Choice of three-unit and six-unit models

- Available with built-in steam super heater

- Microprocessor programmable high accuracy temperature control

- Built-in pressure regulators and air flow-meters

Electrically heated baths for determining existent gum in aircraft turbine fuels by steam-jet evaporation and in motor and aviation gasolines by air-jet evaporation. Fully insulated, aluminium block design assures safe, efficient high temperature operation. Equipped with air/steam pressure regulator with gauge and a flowmeter for adjusting air flow per ASTM specifications. Stainless steel jets deliver air or steam flow to the test wells through removable brass conical adapters. Microprocessor PID control provides quick temperature stabilization without overshoot, and the bath is protected by an over temperature control circuit that interrupts power should bath temperature exceed a programmed cut-off point. Dual LED displays provide actual and setpoint temperature values in ?C/?F format. Communications software (RS232, etc.), ramp-to-set and other enhanced features are available as extra cost options. Contact your Koehler representative for information.

Model K33800 with Built-in Superheater

Six-unit bath with a built-in thermostatically controlled superheater which delivers dried steam to the bath inlet for steam-jet method testing of aircraft turbine fuels. Has digital indicating solid state bath temperature control with digital setpoint and display.

Model K33700

Six-unit bath without built-in superheater.

Model K33780

Three-unit bath without built-in superheater. All controls are housed in the bath cabinet.

Specifications

- Conforms to the specifications of: ASTM D381; IP 131; ISO 6246; DIN 51784;FTM 791-3302; NF M 07-004

- Testing Capacity - K33800 and K33700 : 6 sample beakers , K33780 and K33781 : 3 sample beakers

- Maximum Temperature: 475?F (246?C)

- Temperature Control Stability: ?1?F (?0.5?C)

- Bath Configuration: machined aluminium block with multiple cartridge heaters

- Heater Range - K33800 and K33700: 0-3000W , K33780 and K33781: 0-1500W

- Superheater: (Model K33800 only) Superheating chamber and condensate trap constructed of stainless steel Solid state thermoregulator (0-550?F) Heater Range: 0-1500W

Electrical Requirements

- K33700: 220-240V 50/60Hz, Single Phase, 13.6A

- K33800: 220-240V 50/60Hz, Single Phase, 20.4A

- K33780: 115V 60Hz, Single Phase, 13.0A

- K33781: 220-240V 50/60Hz, Single Phase, 6.8A

Included Accessories

- Conical Brass Adapters for air/steam jets

Dimensions ( lxwxh,in.(cm), Net Weight)

- K33800: 32.1/2x20x20 (83x51x51) , 230 lbs (104.3kg)

- K33780: 32.1/2x11x19 (83x28x48) , 85 lbs (38.6kg)

- K33700: Bath - 28x20x16 (71x51x41) , 203 lbs (92.1kg)

Shipping Information (Shipping Weight , Dimensions)

- K33800: 313 lbs (142kg) , 17.2 Cu. ft.

- K33780: 140 lbs (63.5kg) , 8.3 Cu. ft.

- K33700: 271 lbs (123kg) , 13.7 Cu. ft.

Request Quote