Test Method

The ability of a lubricating oil to separate from water and resist emulsification is an important performance characteristic for applications involving water contamination and turbulence. Water separability is determined by stirring equal volumes of water and sample together at a controlled temperature to form an emulsion and observing the time required for separation of the emulsion to occur. This method is suitable for petroleum oils and synthetic fluids

Water Separability Tester

- Tests emulsion characteristics of lubricating oils

- Seven sample capacity

- Movable digital stirrer with microprocessor control incorporates advanced features for flexibility and ease of operation

- Clear, illuminated heating bath provides excellent visibility

- Microprocessor temperature control with digital display and built-in protection against over temperature and low liquid level hazards

- Conforms to ASTM, ISO and related standards for water separability testing

- Optional sensor for direct measurement of sample temperature

- With built in drain for convenient draining of bath medium

Seven-sample Water Separability Tester provides full visibility and microprocessor control of all functions for simplified, accurate testing of up to seven samples at a time. Use for specification of new oils and monitoring of in-service petroleum oils and synthetic fluids.

Seven position heating bath

A full visibility bath immerses seven 100mL cylinders at the proper depth per ASTM and ISO specifications. Sample cylinders are held securely in place by stainless steel supports inside the bath. A microprocessor based heater controls bath operating controls bath fluid temperature with greater than ?1?C accuracy and stability throughout the operating range of 25?C to 84?C. Large LED readouts display setpoint and actual temperatures in Celsius or Fahrenheit scale at the operator's option. For most samples, ASTM/ISO sample temperatures of 54?C and 82?C are attained within 10 minutes after placement of the test cylinders into the stabilized bath. Clear polycarbonate tank has backlighting for excellent visibility when viewing emulsion separations in the test cylinders. Cut-off circuits for low water level and over-temperature conditions provide protection in the event of equipment malfunction. Easy removal of top plate for filling or cleaning the bath. Polycarbonate jar is encased in a Polyester-Epoxy finished steel housing with a protective distortion-free viewing window and a solid foundation.

Microprocessor sample stirrer

To avoid sample movement, the sample stirrer housing pivots to each test position in the bath and locks securely in place at the required position in relation to the 100mL sample cylinder. The digital stirrer offers complete flexibility for test duration and stirring speed at the push of a button. Operating speed and count down time are prominently displayed on a large backlit LCD panel. A wide operating range of 0-2000rpm permits in-house customized testing with ?1rpm accuracy, and the operator may select a stirring time of up to 99.99 minutes. At the end of the selected interval, the stirrer automatically shuts off and alerts the operator with audible and visual signals that the settling period has commenced. For added convenience, all test parameters are stored in memory and repeated in subsequent tests until they are changed by the operator. Engaging the stirrer mechanism is visible to the operator and housed in a clear tube for added safety.

Specifications

- Conforms to the specifications of : ASTM D1401, D6074, D6158; ISO 6614; DIN 51599; FTM 791-3201; NF T 60-125

- Stirrer Range: 0-2000rpm

- Accuracy: ?1.0rpm

- Drive: 1/10hp (75W), high torque

- Bath Temperature Range: 25?C to 84?C

- Control Stability: ?0.05?C

- Capacity: seven (7) 100mL graduated cylinders

- Construction: Clear polycarbonate tank 10"x11.25"x9.5" (25.5x28x24cm)

- Medium: Water or white technical oil

- Medium Capacity: 15.15L (4 gal)

- Electrical Requirements: 115V, 60Hz, Single Phase, 12A ; 220-240V 50/60 Hz, Single Phase, 12A

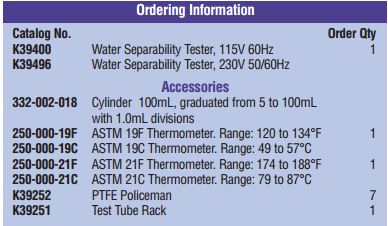

Included Accessories

- Seven 100mL Cylinders

Dimensions

- lxwxh, in.(cm) : 20.75x15.25x29.5 (52.7x38.75x 74.9)

- Net Weight: 78 lbs (35.5kg)

Shipping Information

- Shipping Weight: 102 lbs (46.3kg)

- Dimensions: 6.7 Cu. ft.

Specifications

- Conforms to the specifications of : ASTM D6082

- Temperature Control: Digital Setpoint and Displays ?C/?F switchable , Built-in Over temperature Cut-off Protection

Request Quote