Test Method

Measures the ability of a grease to protect a bearing against corrosion in the presence of water. Two sets of grease-coated bearings per station are partially immersed in water and rotated at a speed of 80 rpm in a sequence of running and resting periods. At the end of the test, the raceways of the bearing outer rings are inspected for rust.

K94454 Corrosion Tester

The Corrosion Tester K9445X has been developed for testing lubricating greases on their corrosion inhabiting characteristics in rolling bearings in the presence of either distilled or demineralized water, or salt water or synthetic sea water and under no applied load. It can also be used to test the corrosion inhibiting characteristics of lubricating oils.

Water contamination can occur in cases where bearing housings are mounted outdoors, in machines regularly subject to water or steam - papermaking machines, food-processing machines - or in under water applications. Lubricating greases consist of various components which chemically may look alike. Small changes or differences in composition, different suppliers or changes in the process of making greases may result in great performance differences of corrosion inhibiting.

Measurement Principle

Double row self-aligning ball bearings are packed with grease and run to distribute the grease evenly. The bearings are exposed to either distilled water, synthetic sea water or sodium chloride solution, and the test rig is operated under alternating running and standing conditions for one week. After cleaning, the bearing races are examined for corrosion and rated "0" to "5".

The test can be run with greases and oils and variations with regards to the test medium are possible. The touch screen panel allows easy to setup sequences to define your customized test setup or run the standard test. The customize test setup gives the possibility of a free adjustment of running hours and waiting hours.

Specifications

- Conforms to the specifications of : ASTM D6138; ISO 11007; DIN 51802; BS 2000 pt 220; IP 220; SIS 155130 and NFT 60-135

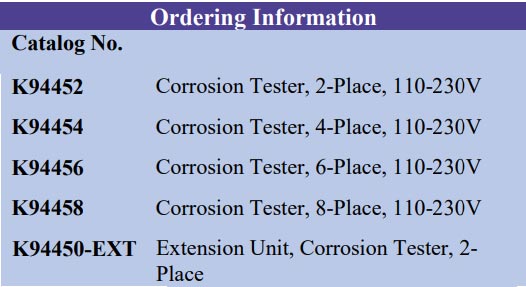

- Test Capacity : K94452: 2 test positions

K94454: 4 test positions

K94456: 6 test positions

K94458: 8 test positions

*An extension unit of 2 test bearings can be purchased and added at any time as long as the maximum number of 8 positions is not exceeded - Test Bearings : Double row, self-aligning ball bearings, 1306K

- Test Speed : adjustable, predefined, 80 rpm

- Test Time : standard 168 h or customized

- PLC : Touchscreen PLC

- Electrical Requirements : 110 - 230V, 50/60Hz, 150W max

- Dimensions (W x D x H) : Basic Station (2-places): 480 x 250 x 200 mm

Extension Unit: 260 x 230 x 170 mm

Included Accessories

- Test Bearings (1306) - 2, 4, 6 or 8 depending on configuration

- Multirange Power Supply

- Documentation