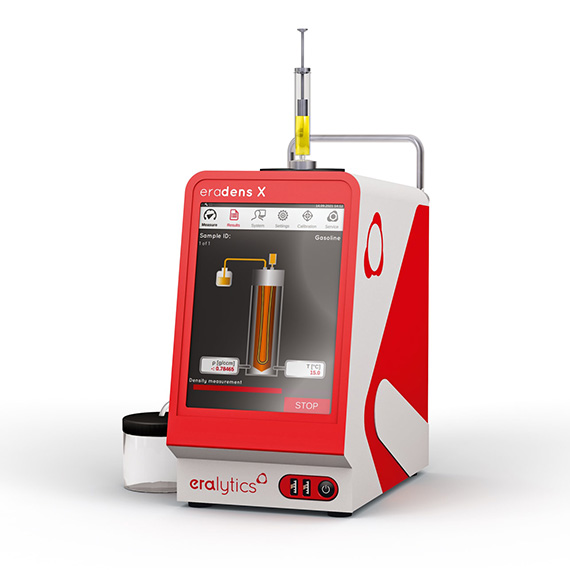

ERADENS X is the world?s smallest and lightest high-precision density meter measuring in full compliance with ASTM D4052 and ISO 12185. Its revolutionary vertically aligned x-oscillating metal U-tube design is extremely reliable and insensitive to toughest ambient conditions, making ERADENS X the perfect solution for density testing in stationary as well as in mobile laboratories.

Xtra Easy

The large industry-proven color touchscreen with its intuitive user interface design makes your daily measurement routine highly efficient and keeps operation easy, even with gloves on. With its unique sample introduction from the top ERADENS X is equally easy to operate for right-handed and left-handed persons. Results are displayed on the large touch screen and can be printed, exported via USB, or directly transferred to a PC or LIMS via ethernet connection.

Xtra Rugged & Compact

ERADENS X is built in a corrosion-resistant aluminum housing and has no moving parts. The revolutionary design featuring a vertically aligned x-oscillating metal U-tube makes ERADENS X an extremely robust and versatile analyzer that is unaffected by shocks and vibrations. It is therefore the perfect solution for highly accurate testing even under extreme conditions.

ERADENS X is the analyzer with the smallest footprint on the market, still offering maximum ease of use and operator convenience. The compact dimensions and lightweight instrument design offer true portability on-site and require minimum bench space in the lab.

Xtra Accurate

With the x-oscillating metal U-tube technology inside, ERADENS X provides density results with 5-digit precision. eralytics unique full range viscosity correction ensures that the highest possible accuracy is achieved over the wide temperature range of 0 - 100 °C.

Innovative FillingProofTM Technology

The vertical alignment of the U-tube minimizes the probability of air bubbles getting trapped inside the density cell. For the verification of the bubble-free filling, eralytics has developed FillingProofTM. In contrast to error-prone optical methods, the change in the density as a function of applied pressure is used to detect even the smallest bubbles providing reliable results also for non-transparent samples such as crude oil.

Technical Specifications

| Standard | ASTM D4052, D5002, ISO 12185 |

| Density Range | 0 - 3 g/cm3 |

| Temperature Range | 0 °C to 100 °C (32 ?F to 212 ?F) |

| Density Repeatability (SD) | 0.000005 g/cm3 (according to ISO 5725) |

| Density Resolution | 0.00001 g/cm3 |

| Temperature Accuracy | 0.02 °C (0.04 ?F) |

| Pressure Range | 0 - 10 bar (145 psi) absolute pressure |

| Measurement Time | 15 sec (after temperature equilibration) |

| Sample Volume | 2 mL |

| Oscillating Tube | Hastelloy |

| Bubble Detection (patent pending) | FillingProofTM - automated bubble detection and bubble quantification |

| Viscosity Correction (patent pending) | yes - full range correction |

| Tables & Functions | API, sugar, alcohol, etc, and freely programmable tables |

| Special Features | Integrated fully-automated drying pump, built-in ambient pressure sensor |

| Result Database | Over 100 000 detailed test reports stored |

| Remote Service | Remote service capability via Ethernet |

| Interfaces | Built-in PC with Ethernet, 4 x front and rear USB and RS232 interfaces; Wi-Fi via USB dongle Direct LIMS connectivity via LAN, output to printer or PC and export as CSV or PDF Optional input by keyboard, mouse, and barcode reader |

| Display | Industry-proven 8.4" multilingual color touchscreen |

| Power Requirements | 85 - 264 V AC 47- 463 Hz, max 150 W |

| Operating Conditions | 5 °C - 45 °C up to 90 % rel. humidity (non-condensing) |

| Dimensions & Weight | W x D x H = 15,5 x 26 x 28 cm (6.1 x 10.2 x 11 in); 7 kg (15 lb) |