MICROTEST three point bending and tensile/compression modules have been specifically designed to observe the high stress region of the sample within a SEM or under an optical microscope. Windows software sets drive parameters and displays the stress/strain curve live on the PC screen. Loadcells from 75N to 2kN cover most applications, with extension rates from 0.05mm/min to 5mm/min. Special versions can be manufactured to customers requirements. All modules are controlled from Microtest tensile testing software.

As with all Deben testing modules, control is via PC using the MICROTEST tensile testing software.

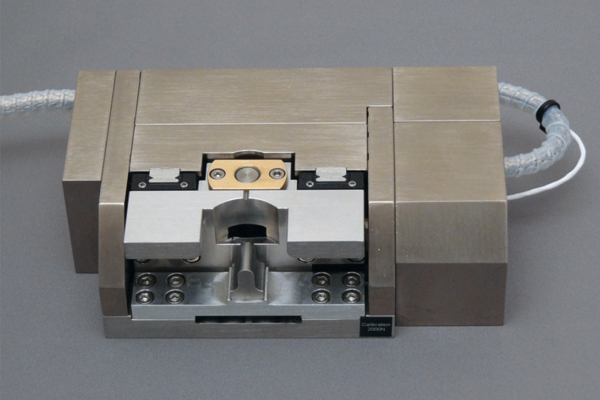

In conventional three-point bending, the sample is supported on two outer points, and deformed by driving the third central point downwards. For SEM use we have inverted the technique.

The sample sits on the central fixed point, and the two outer points are driven downwards. This has two benefits ? the high strain region of interest is at the top for ease of viewing, and stays in focus because the height does not change.

The maximum load for the standard unit is 300N, with deformation speeds ranging from 0.05mm/min to 5mm/min. A high load version is also available for loads up to 2KN. Standard sample width is 40mm. The top and bottom jaws (points) can be easily changed for different sample configurations, for example to allow indentation studies or four point bending.

This module is designed for vertical three point bending only, for horizontal three point bending we would recommend a tensile stage with optional three or four point bending clamps fitted.

<